Fiber reinforced polymer (FRP) market is rapidly changing the dynamics of the construction industry worldwide. With reinforced composites gaining a lot of attention due to their excellent strength-to-weight ratio, corrosion resistance, and high durability, fiber reinforced polymers are on the list of world-changing super materials. The use of composites rebar for infrastructure reinforcements has remained a hot topic in leading engineering organizations for over two decades. The unique ability of FRP for flexible design is giving true value to the composites and is opening doors to new possibilities in the fiber reinforced polymer industry.

The chief problem faced with the use of metals in construction is the fact that they eventually succumb to corrosion and deterioration, Additional problems include the high costs for rehabilitating the structures and safety problems in construction zones. A study suggests that over 25% of the total construction failures are due to corrosion. FRP materials, on other hand, are providing a major solution with their non-corrosive and high strength properties. Their light weight feature is contributing further to minimize the issues of material assembling and transportation. Increased shelf life of FRP-based product will lead to the rapid expansion of the application landscape, thereby pushing fiber reinforced polymer industry to greater heights. In essence, the inference is that, fiber reinforced polymer materials have successfully emerged as an alternative, highly reliable material in the construction world.

While fiber reinforced polymer market finds extensive applications in the construction and infrastructural development sectors, its applications can also be diversely found in marine, automotive, wind, aerospace, and water treatment industries. The elevating demand for light weight composites in aircraft and other commercial applications is likely to grab maximum share of overall advanced polymer composites market, which is poised to exhibit a Y-O-Y growth of 7% over the period of 2016-2024.

Fiber reinforced polymer industry comprises four main ingredients, where each ingredient plays an important role in determining the properties of the composite. The ingredients and their vital functions are as given below:

- Fiberglass reinforcements – include glass, carbon, and aramid fiber, which provide strength and stiffness to the material. Glass fibers represent 95% of the composites market and their production for composites is estimated to be at 250,000 tons per year.

- Resins – include polyester, vinyl ester, and epoxy resins, which works as a binding agent and protects the fibers. Based on the type of resins used, the final FRP industry products will differ on parameters such as corrosiveness and tensile strength.

- Additives & Fillers – customize the polymer properties and help improve water resistance, weathering, dimensional stability, and temperature resistance.

- Surface Finishes – are used to add UV protection and corrosion resistance.

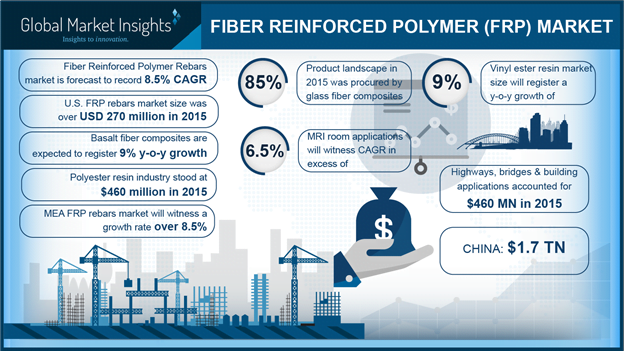

The exceptional benefits of FRP materials leads to improved performance of construction applications such as bridges, buildings, roads, railways, and marine structures. The rapid infrastructural development and improved government spending on highways & bridges is garnering huge profits for the fiber reinforced polymer market. Intensive research in FRP market for replacing the concrete structures has become increasingly active, fueled by the need to surpass the limitations of conventional materials. FRP rebar is a lightweight spiral wrapped fiberglass rod, which is highly preferred as an alternative over steel concrete reinforcement. As per a report, Fiber Reinforced Polymer (FRP) Rebars Market is set to record a CAGR of over 8.5% over the period of 2016-2024.

FRP industry has witnessed a remarkable step in embedding composite polymer with Aslan 100 GFRP (glass fiber reinforced polymer) rebars in the Elkhorn North Bridge project. The project required redecking and repairing of the bridge, in which, the Nebraska Department chose to use non-corrosive FRP rebars to replace the traditional steel bars to extend the expected service life of the deck. This project won the ACI Award of Excellence by enhancing sustainability and reducing density by 25% as compared to steel.

Why is FRP rapidly replacing steel reinforcements?

- Greater tensile strength than steel

- One-fourth the weight of steel

- Resistant to chemical attacks and chloride ions

- Electrically & thermally non-conductive

- Transparent to radar frequencies and magnetic fields

Another masterpiece in the fiber reinforced polymer industry is the Minto Bridge, standing as a crown jewel of Canada. In this project, prefabricated FRP bridge deck panels were installed in numbers, which solved numerous construction challenges and provided aesthetics & sustainability to the infrastructure. These two projects have set a worldwide agenda for all the manufactures to adopt FRP and composites to their full potential, promoting durability and environmental safety.

Presently, integrated design structure of FRP is one of the key trends in fiber reinforced polymer market, which is unlocking series of possible opportunities in casting flexible designs. This factor is adding to the growth prospects of FRP market in the marine structures & waterfronts. Water vessels are prone to steel corrosion and abrasion. The FRP materials offer high structural design synthesis and economical repair alternatives by almost nullifying the corrosion rate.

Many key FRP industry players are also focusing on FRP doors and windows which are highly durable & dustproof, sound insulated, termite free, and require minimal maintenance in comparison to metal or wooden doors. The rapid growth in the Composite Doors & Windows Market is worth noticing, which is based on commercial, residential, and industrial application.

While fiber reinforced polymer industry has already proven its worth, the current challenge is to make them cost-effective. The penetration of these advanced materials in the construction sector has observed a steady expansion over the recent years. Armed with a wide gamut of advantages, FRP industry is promising to offer much larger business opportunities. Fiber reinforced polymer market players are focusing on developing specialized products to capitalize the most of FRP industry stake.

Global Market Insights, Inc. has an exclusive collection of HVAC and construction market reports as well as newly published research on polymers and advanced materials at https://www.gminsights.com/industry-reports/polymers-and-advanced-materials .