1.0 nF

EIA/MIL: 102

nF: Nanofarad

Every engineering student or high school STEM student probably knows what a capacitor. Therefore, defining it may not be necessary but here we go. A capacitor is a passive two-terminal electronic component that stores electrical energy in an electric field. It is used to add capacitance to a circuit which makes it an important part of every electronics project. It is also important to know that the physical form of capacitors vary which means there are different capacitor types currently in use.

Most capacitors are built to have two electrical conductors. The conductors are generally metal plates which are separated by a dielectric medium. The conductor used could be a foil, thin metal film or an electrolyte. The dielectric medium separating the conductors are non-conductors themselves and can be made from glass, ceramics, air, mica, or plastic film. From these descriptions, it is obvious that capacitors come in different configurations and types. To help you make easy decisions when choosing a capacitor, this article will explore the common types of capacitors available to you.

The 7 Common Capacitors for Your Electronics Project

Ceramic Capacitors – The ceramic capacitor is a capacitor that makes use of a ceramic as a dielectric medium to separate the conductors in the capacitor. This means these capacitors are named after the dielectric medium used and their development.

The use of ceramics and ceramic capacitors provide multiple benefits to the user. These benefits include:

- A low loss factor which guarantees a reasonable level of stability when used.

- Its tight tolerances make it the commonly used option in RF circuits.

- Monolithic multi-layer ceramics can also be used as by-pass capacitors.

- It is relatively more affordable and it delivers high capacitance for your applications.

The common ceramic capacitor used are the COG – for low capacitance values, the X7R – for higher capacitance, and the Z5U is used for higher capacitance but delivers lower stability than COG or X7R.

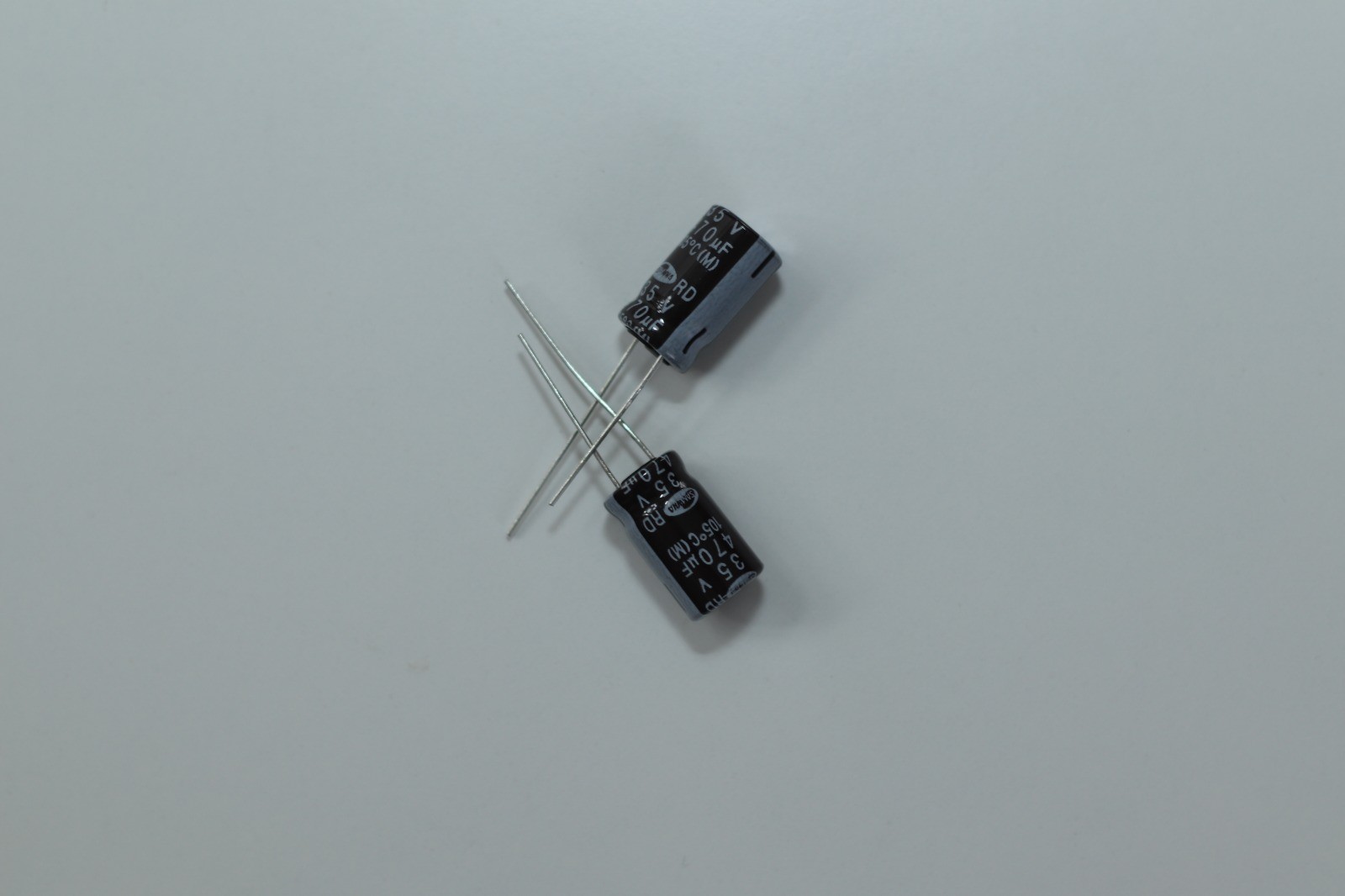

Electrolytic Capacitors – The electrolytic capacitor takes its name from its build. In its case, an electrolyte-soaked sheet is generally placed between two aluminum conductor films. The electrolytic capacitor is the most common leaded type used. When used, it is recommended that the rated working voltage should not be exceeded. This is because electrolytic capacitors are prone to damage.

The applications and benefits of using an electrolytic capacitor include:

- It is a polarized capacitor commonly used in smoothening or filtering power supply rails.

- Its low stability level means it should be used in non-critical applications such as in timing elements.

- They do not function well in high-frequency environments. Electrolytic capacitors should be used for frequencies lower than 100KHZ

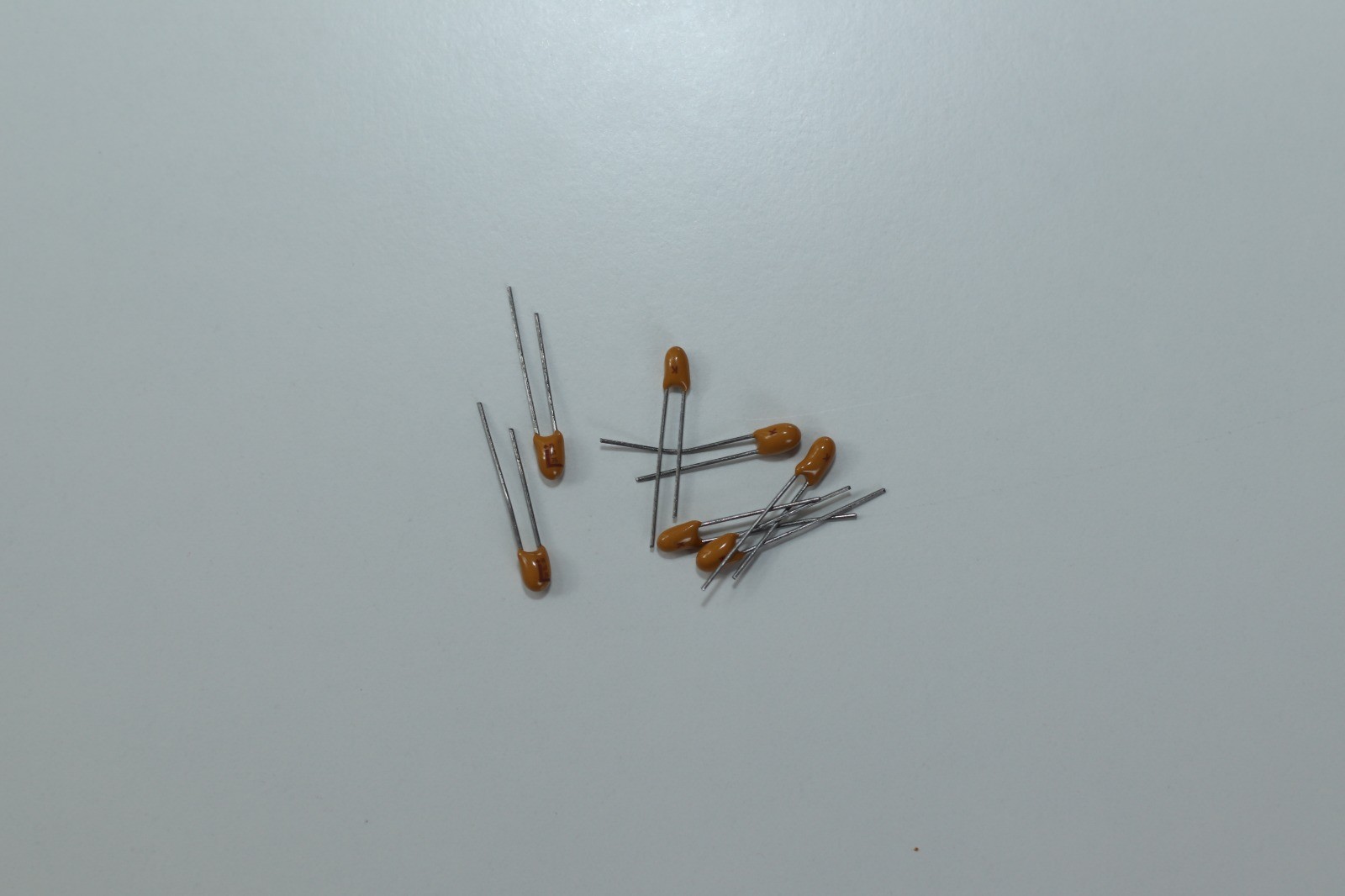

Tantalum Capacitors – Tantalum capacitors are popular used in applications where the physical size of a capacitor is a consideration. This is because they are much smaller than the traditional aluminum capacitors used in different devices. The capacitors build integrates a film of oxide and tantalum. These serve as the conductor and dielectric medium. Tantalum generally do not have high working voltages and coupled with their sizes, these features make them popular with electronics creators.

The applications and benefits of Tantalum include:

- They are polarized capacitors and may combust under excessive stress.

- They have a lower series equivalent resistance compared to other options.

- The generally have a lower voltage and 35 volts is usually the maximum of any Tantalum capacitor.

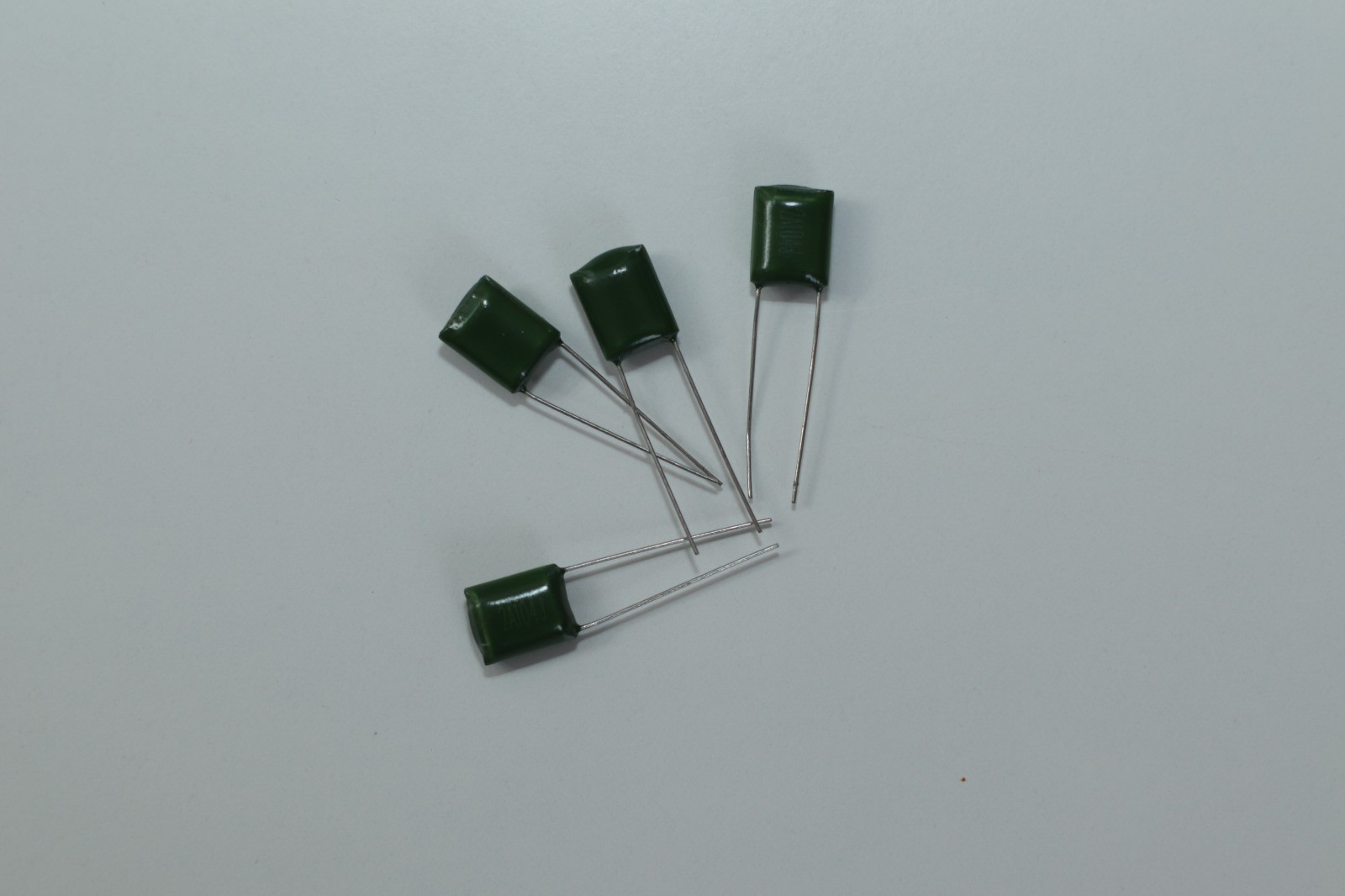

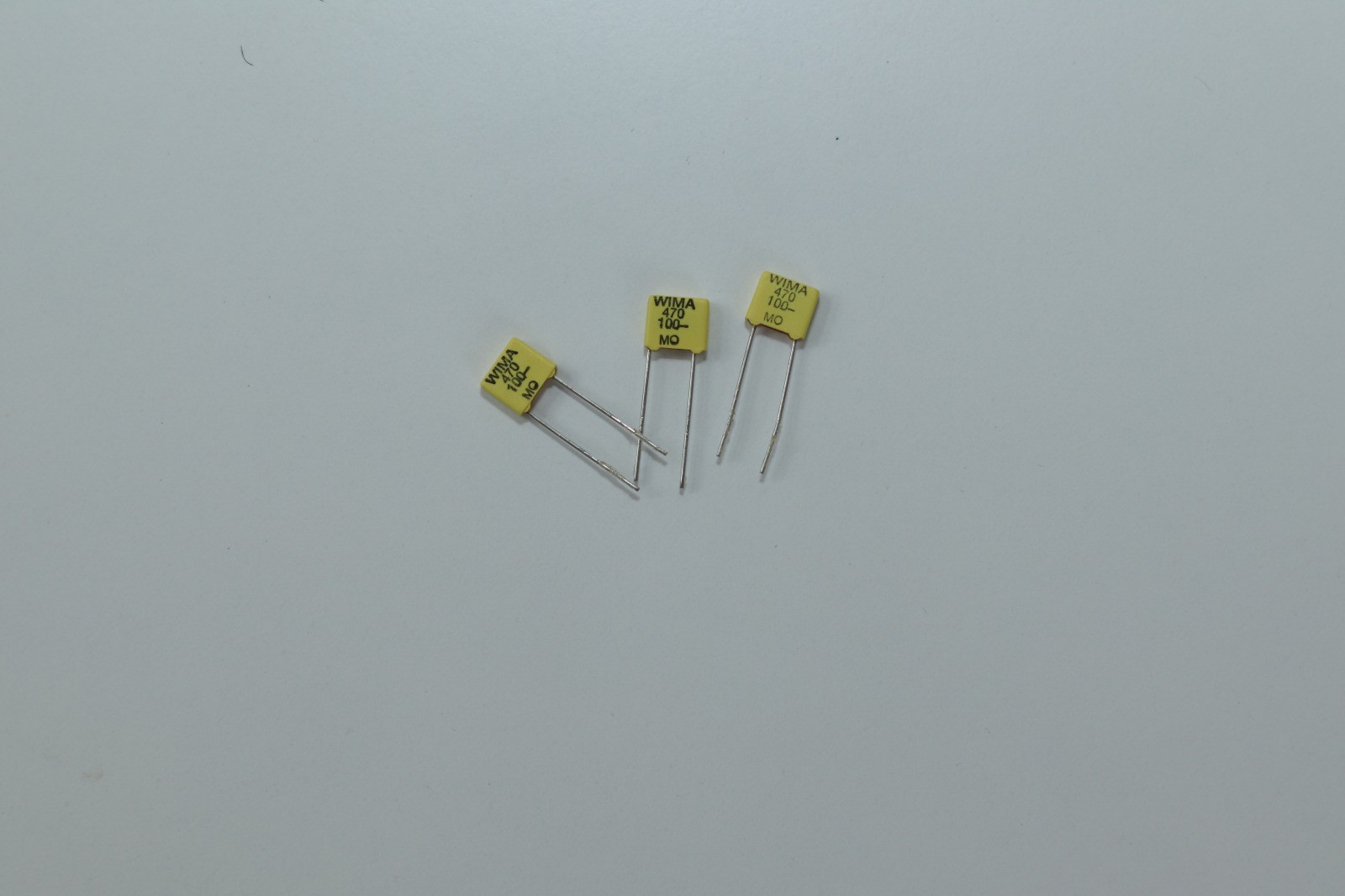

Polyester Capacitors – If the name ‘polyester’ does not ring a bell, do not fret. Polyester capacitors are also called different names such as a Mylar or PET capacitor. The naming options is due to the material used with these capacitors.

Mylar is the materials used as a dielectric medium and this material is sometimes called polyester or Polyethylene terephthalate (PET). The properties, applications, and benefits of polyester capacitors include:

- Polyester offers enhanced dielectric strength which makes it possible to develop small capacitors with high voltage.

- They are generally green in color and are affordable. The general color of this capacitor has also earned it the name ‘green caps’.

- A low tolerance of less than 10% means these capacitors can be used in diverse applications.

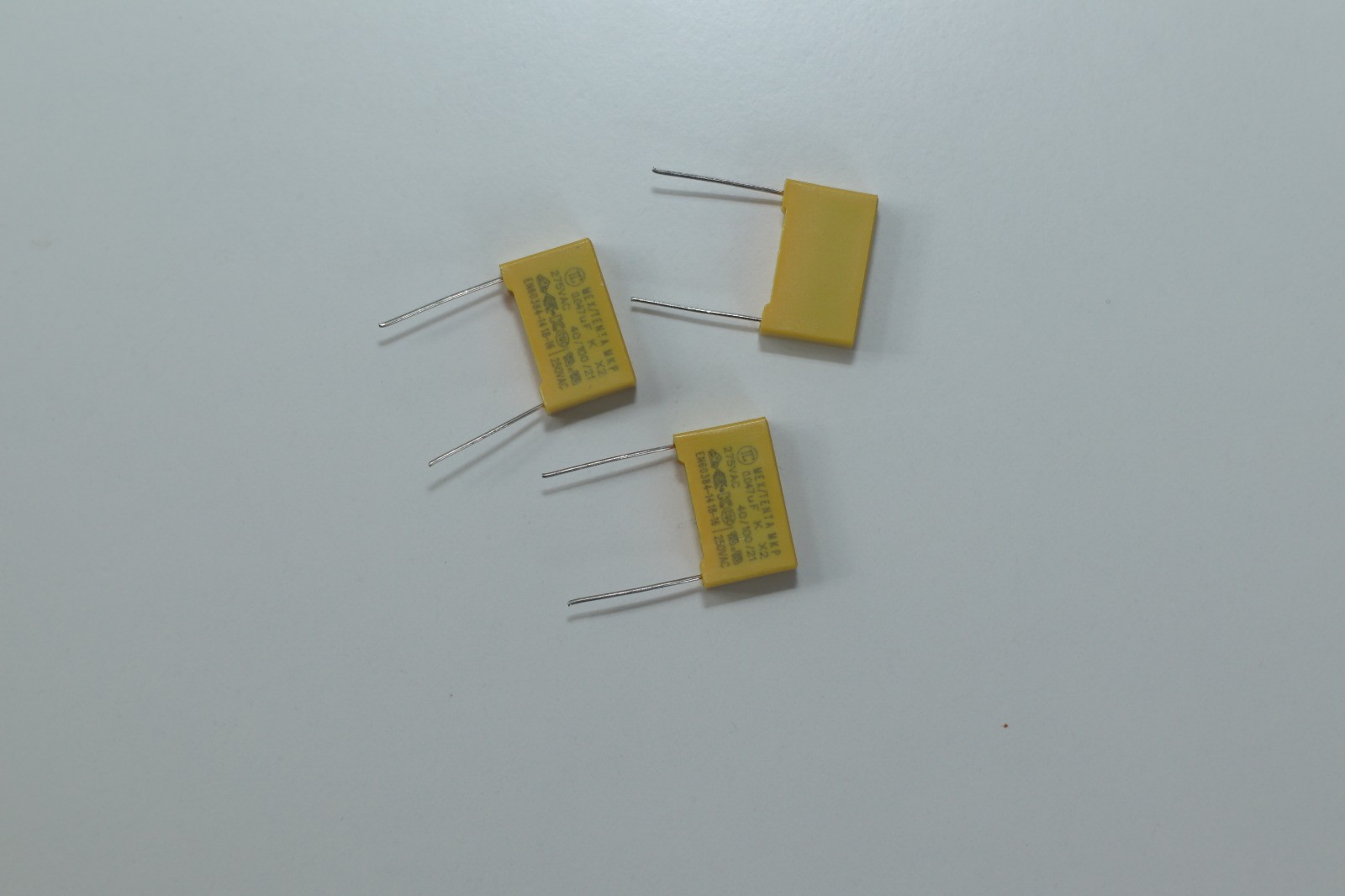

Polycarbonate Capacitors – Once again, the dielectric medium used lends its name to a capacitor. The polycarbonate capacitor consists of a polycarbonate dielectric that delivers stability and high tolerance. Although Polycarbonate capacitors are common, it is usually used as a second option to other capacitor types. The polycarbonate dielectric medium is constructed in a foil format with metallic electrodes serving as the conductors.

The properties, applications, and benefits of a polycarbonate capacitor includes:

- A high insulation resistance and a low dissipation factor.

- It can operate optimally in temperatures as low as -55C and as high as 125C.

- Polycarbonate capacitors can be self-healing as it vaporizes defective electrodes which restores the capacitor to life.

Polystyrene Capacitor – Although polystyrene capacitors are not widely used as others on this list, they are quite common and have interesting properties. Firstly, the capacitors make use of polystyrene dielectric medium between its conductors. The characteristics of polystyrene capacitors are high insulation, low leakage, and excellent temperature stability.

They are also relatively affordable and their properties, applications, and benefits include:

- They are generally applied in audio devices or hardware.

- They exhibit low leakage and low dielectric absorption which means a longer life span when used.

- They are not as available for purchase like other options due to their limited use in electronics.

Polypropylene Capacitor – Propylene capacitors are generally available or built as leaded components. These capacitors make use of a polypropylene dielectric which means they can be used where high degree of tolerance is a consideration. Polypropylene capacitors are commonly used in loud speakers as it guarantees enhanced-performance.

The properties and benefits of polypropylene includes:

- They exhibit high stability which makes them best for applications where capacitance stability is an important consideration.

- They are only available as leaded components and cannot be surface-mounted.

Summary

The common capacitor types listed here are versatile options that can be used in most applications. But it is important to note that some capacitors function better in certain applications when compared to others. Thus, it is important to always consider the application you need a capacitor for before choosing any of these capacitor types listed here.