Among the many popular tourist sites in Rome is an impressive 2000-year-old mausoleum along the Via Appia known as the Tomb of Caecilia Metella, a noblewoman who lived in the first century CE. Lord Byron was among those who marveled at the structure, even referencing it in his epic poem Childe Harold’s Pilgrimage (1812-1818). Now scientists have analyzed samples of the ancient concrete used to build the tomb, describing their findings in a paper published in October in the Journal of the American Ceramic Society.

“The construction of this very innovative and robust monument and landmark on the Via Appia Antica indicates that [Caecilia Metella] was held in high respect,” said co-author Marie Jackson, a geophysicist at the University of Utah. “And the concrete fabric 2,050 years later reflects a strong and resilient presence.”

Like today’s Portland cement (a basic ingredient of modern concrete), ancient Roman concrete was basically a mix of a semi-liquid mortar and aggregate. Portland cement is typically made by heating limestone and clay (as well as sandstone, ash, chalk, and iron) in a kiln. The resulting clinker is then ground into a fine powder, with just a touch of added gypsum—the better to achieve a smooth, flat surface. But the aggregate used to make Roman concrete was made up fist-size pieces of stone or bricks

In his treatise de Architectura (circa 30 CE), the Roman architect and engineer Vitruvius wrote about how to build concrete walls for funerary structures that could endure for a long time without falling into ruins. He recommended the walls be at least two feet thick, made of either “squared red stone or of brick or lava laid in courses.” The brick or volcanic rock aggregate should be bound with mortar comprised of hydrated lime and porous fragments of glass and crystals from volcanic eruptions (known as volcanic tephra).

Jackson has been studying the unusual properties of ancient Roman concrete for many years. For instance, she and several colleagues have analyzed the mortar used in the concrete that makes up the Markets of Trajan, built between 100 and 110 CE (likely the world’s oldest shopping mall). They were particularly interested in the “glue” used in the material’s binding phase: a calcium-aluminum-silicate-hydrate (C-A-S-H), augmented with crystals of stratlingite. They found that the stratlingite crystals blocked the formation and spread of microcracks in the mortar, which could have led to larger fractures in the structures.

In 2017, Jackson co-authored a paper analyzing the concrete form the ruins of sea walls along Italy’s Mediterranean coast, which have stood for two millennia despite the harsh marine environment. The constant salt-water waves crashing against the walls would have long ago reduced modern concrete walls to rubble, but the Roman sea walls seem to have actually gotten stronger.

Jackson and her colleagues found that the secret to that longevity was a special recipe, involving a combination of rare crystals and a porous mineral. Specifically, exposure to sea water generated chemical reactions inside the concrete, causing aluminum tobermorite crystals to form out of phillipsite, a common mineral found in volcanic ash. The crystals bound to the rocks, once again preventing the formation and propagation of cracks that would have otherwise weakened the structures.

So naturally Jackson was intrigued by the Tomb of Caecilia Metella, widely considered to be one of the best-preserved monuments on the Appian Way. Jackson visited the tomb back in June 2006, when she took small samples of the mortar for analysis. Despite the day of her visit being quite warm, she recalled that once inside the sepulchral corridor, the air was very cool and moist. “The atmosphere was very tranquil, except for the fluttering of pigeons in the open center of the circular structure,” Jackson said.

Carole Raddato/CC BY-SA 2.0

Almost nothing is known about Caecilia Metella, the noblewoman whose remains were once interred in the tomb, other than that she was the daughter of a Roman consul, Quintus Caecilius Metellus Creticus. She married Marcus Licinius Crassus, whose father (of the same name) was part of the First Triumvirate, along with Julius Caesar and Pompey the Great. It was likely her son—also named Marcus Licinius Crassus, because why make it easy for historians to keep track of the family genealogy?—who ordered the construction of the mausoleum, likely built sometimes between 30 and 10 BCE.

A marble sarcophagus housed in Palazzo Farnese is supposedly from the Tomb of Caecilia Metella, but it was probably not the noblewoman’s since it dates to between 180 and 190 CE. Besides, cremation was a more common burial custom at the time of the lady’s demise, and thus historians believe that the tomb’s cella probably once held a funerary urn, rather than some kind of sarcophagus.

It’s the structure of the the tomb itself that is of most interest to scientists like Jackson and her colleagues. The mausoleum is perched atop a hill. There is a cylindrical rotunda atop a square podium, with an attached castle to the rear that was built sometime in the 14th century. The exterior bears a plaque with the inscription, “To Caecilia Metella, daughter of Quintus Creticus [and wife] of Crassus.”

Marie Jackson

The foundation is built partly on tuff rock (volcanic ash that has been compacted under pressure) and lava rock from an ancient flow that once covered the area some 260,000 years ago. The podium and rotunda are both comprised of several layers of thick concrete, surrounded by travertine blocks as a frame while the concrete layers formed and hardened. The tower walls are 24 feet thick. Originally there would have been a conical earthen mound on top, but it was later replaced with medieval battlements.

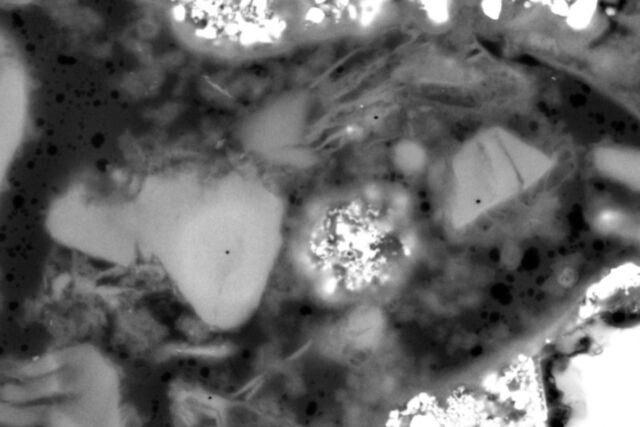

To take a closer look at the tomb mortar’s microstructure, Jackson teamed up with MIT colleagues Linda Seymour and Admir Masic, as well as Lawrence Berkeley Lab’s Nobumichi Tamura. Tamura analyzed the samples at the Advanced Light Source, which helped them identify both the many different minerals contained in the samples and their orientation. The ALS beam line produces powerful x-ray beams about the size of a micron, which can penetrate through the entire thickness of the samples, per Tamura. The team also imaged the samples with scanning electron microscopy.

They discovered that the tomb’s mortar was similar to that used in the walls of the Markets of Trajan: volcanic tephra from the Pozzolane Rosse pyroclastic flow, binding together large chunks of brick and lava aggregate. However, the tephra used in the tomb’s mortar contained much more potassium-rich leucite. Over the centuries, rainwater and groundwater seeped through the tomb’s walls, which dissolved the leucite and released the potassium. This would be a disaster in modern concrete, producing micro-cracking and serious deterioration of the structure.

That obviously didn’t happen with the tomb. But why? Jackson et al. determined that the potassium in the mortar dissolved in turn and effectively reconfigured the C-A-S-H binding phase. Some parts remained intact even after over 2000 years, while other areas looked more wispy and showed some signs of splitting. In fact, the structure somewhat resembled that of nanocrystals.

Marie Jackson

“It turns out that the interfacial zones in the ancient Roman concrete of the tomb of Caecilia Metella are constantly evolving through long-term remodeling,” said Masic. “These remodeling processes reinforce interfacial zones and potentially contribute to improved mechanical performance and resistance to failure of the ancient material.”

The more scientists learn about the precise combination of minerals and compounds used in Roman concrete, the closer we get to being able to reproduce those qualities in today’s concrete—such as finding an appropriate substitute (like coal fly ash) for the extremely rare volcanic rock the Romans used. This could reduce the energy emission of producing concrete by as much as 85 percent, and improve significantly on the lifespan of modern concrete structures.

“Focusing on designing modern concretes with constantly reinforcing interfacial zones might provide us with yet another strategy to improve the durability of modern construction materials,” said Masic. “Doing this through the integration of time-proven ‘Roman wisdom’ provides a sustainable strategy that could improve the longevity of our modern solutions by orders of magnitude.”

DOI: Journal of the American Ceramic Society, 2021. 10.1111/jace.18133 (About DOIs).